Greenfield & Brownfield projects

We work closely with clients at every phase of greenfield & brownfield projects from plant investment feasibility assessment, to vendor evaluation and setting up a fully operational plant or a line.

Our approach is industry agnostic and our unique engagement model ensures we work closely with client team to ensure there is seamless co-ordination between all stakeholders.

- Plant Investment feasibility

- Development of project charter

- RFQ creation and bidding process management

- Vendor evaluation and recommendations

- Management of contracts and schedules

- On-site supervision during construction and installation

- Review, monitor and report on project progress and budget

- Commissioning and production start-up support

- Project deliverables, time schedule and risks.

- Start to end, complete project management

- Setting up project delivery office and installing audit & tracking process

- Project Risk Management & Mitigation

Technology & plant transfer

As companies look to relocate plant operations to leverage cost advantages, we engage with them no not only move machines and equipment but also to assess the impact of this on their supply chain develop strategies to mitigate risks.

With a strong network of machine builders in India, we are well placed to help companies localize their machines and equipment to optimize costs.

- Development of project charter

- Goal setting and indigenization strategy

- Vendor evaluation and management

- RFQ creation and bidding process management

- Vendor evaluation and recommendations

- Management of contracts and schedules

- On-site supervision during construction and installation

- Review, monitor and report on project progress and budget

- Start to end, complete project management

- Setting up project delivery office and installing audit & tracking process

- Project Risk Management & Mitigation

Product Engineering

Our product design services aims to provide inventors and innovators with the tools and support they need to bring their ideas into reality.

We work with clients from ideation to designing to rapid prototyping and manufacturing readiness. Our design services enable clients to improve their capability

Product Design Services

- Idea & Concepts

- Bench Marking & Tear Down

- Materials & Manufacturing Applications

- Functional & Manufacturing Feasibility Analysis

CAD & CAE Services

- 3D Modelling, 2D to 3D conversions

- Legacy data conversions

- Kinematics & Mechanism Simulations

- Creation of standard library parts

- Reverse Engineering – Remastering

- CAE - FEA, Static Analysis, CFD

- Finite Element Modelling, Fatigue Analysis

- Thermal Analysis, Crash Analysis

Plant optimization services

There is always scope for improvement and more so in on-going operations.

Our deep experience in setting-up and optimizing manufacturing processes allows us to leverage our skills to deliver exceptional plant optimization services.

With hands-on approach and extensive operational experience we offer creative out of the box ideas

- Manufacturing process optimization

- Machine capacity assessment and enhancement

- Inventory planning & optimization services

- Process automation & digitization services

- Management of engineering resources

- New product launch management services

- Improving reliability and availability of equipment (OEE)

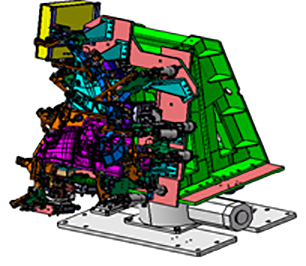

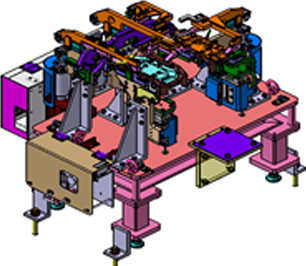

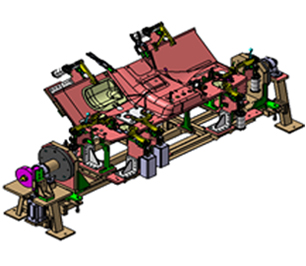

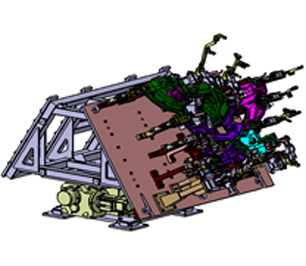

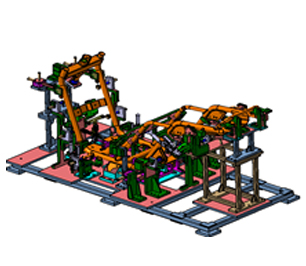

Automotive BIW

We have deep experience in conceptualization, design, manufacturing and on site proving of critical body weld shop fixtures for automotive & non-automotive applications.

With a strong design team backed by start-of the art infrastructure, we offer flexible engagement options for clients to meet their needs. Here are some of the examples of our success stories from the automotive BIW space.

- Part Name: Rear Quarter Inner (RQI) Panel

- Our Customer: Faith Automation

- End Customer: Maruti Suzuki

- Fixture Type: Robotic Spot Welding (Turn table arrangement)

- Part Name: Tailgate Sub-assembly Panel

- Our Customer: Faith Automation

- End Customer: Mahindra & Mahindra

- Fixture Type: Manual Spot Welding Fixture

- Part Name: Dashboard Sub-assembly Panel

- Our Customer: Innovative Automation

- End Customer: Mahindra & Mahindra

- Fixture Type: Manual Spot Welding

- Part Name: Rear Qtr. Inner

- Our Customer: Valiant Systems

- End Customer: TATA Motors

- Fixture Type: Robotic Spot Welding Fixture

- Part Name: Two-Wheeler Chassis

- Our Customer: Vandan Enterprises

- Fixture Type: Manual CO2 Welding

- Part Name: Front Door

- Our Customer: Valiant Systems

- End Customer: VECV

- Fixture Type: Door Fitment Manipulator